About glulam

Structure

Glulam (glued laminated timber) comprises a number of wood laminates glued together. The fibres in the laminates run parallel to the length of the piece. In straight glulam products, the laminates are 45 mm thick. For curved products, the thickness is less, generally 33 mm.

Glulam is a construction material that comes in a range of strength classes. The manufacturing standard for the Swedish market is strength class GL30. Some glulam beams are made by splitting glulam beams of class GL30 to create split timber beams, which then have a strength class of GL28.

Glulam sets no limits on the potential for wood construction techniques.

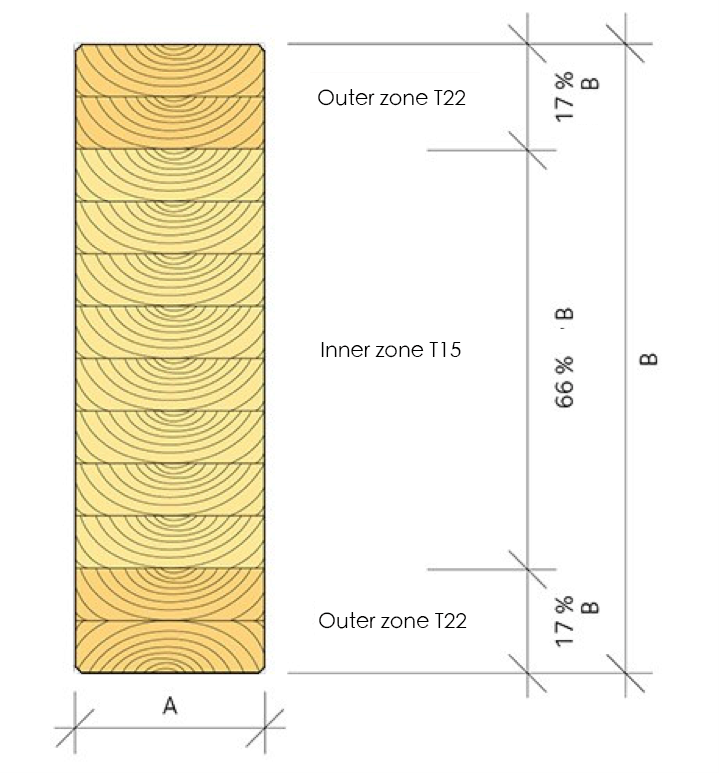

Glulam beams are made with laminates of a higher strength class on the bottom and top, where the maximum tensile and compressive stresses occur. The rest of the cross-section, where the stresses are lower, uses laminates of a lower strength class. The manufacturing method is called combined glulam and is usually indicated with the letter c after the strength class designation. This allows more efficient use of material compared with only using wood of the same strength class.

Alternatively, glulam may be made with laminates of the same high strength class throughout, and this is represented with an h for homogeneous after the strength class designation. Glulam is available in a large number of dimensions. Read more under Range.

Custom manufacture

Where large spans, loads or other circumstances define the design, glulam is made to the drawings and accompanying specifications as required, in consultation with the glulam manufacturer’s structural engineers. Custom-made glulam elements are available in practically any shape and dimension to meet the architect’s vision and other parameters.

Examples of common custom glulam products include curved beams, pitched beams, portals and arches. Contact one of the glulam manufacturers for more information.

Glulam has a good environmental profile in manufacture and use.

Photo: Johan Ardefors.

Why glulam?

- Strength – Glulam is one of the strongest construction materials in relation to its weight.

- Environment – The raw material is renewable. The glulam can be re-used or recycled.

- Aesthetic value – Glulam is a naturally attractive product that people have a strong emotional connection with.

- Energy – Energy use in glulam manufacture is very low compared with other construction materials.

- Durability – Glulam tolerates aggressive environments better than many other construction materials.

- Formability – Glulam can be produced in practically any shape.

- Dimensional stability – Glulam does not twist or bend.

- Fire resistance – Glulam resists fire better than many other construction materials.

- Workability – Glulam can be worked and crafted using both simple hand tools and mechanical tools. Holes and notches can be cut in glulam in consultation with an experienced structural engineer.

Copperhill Mountain Lodge , Åre.

Copperhill Mountain Lodge , Åre.

Glulam is the future!

- Glulam sets no limits on the potential for wood construction techniques.

- The glued laminates make glulam both strong and stiff.

- Glulam is one of the strongest construction materials in relation to its weight. This means that glulam beams can freely span large distances.

- Architects, structural engineers and users have great freedom to create their own shapes using glulam, whether for the structure of a house, a roof for a public building or a wooden bridge.

- Glulam is a construction material that optimises the technical properties of the renewable raw material – wood.

- Glulam is made from individual laminates of construction timber and ensures efficient use of material.

- The laminates are finger-jointed to produce long lengths and then bonded together to create the desired dimension.